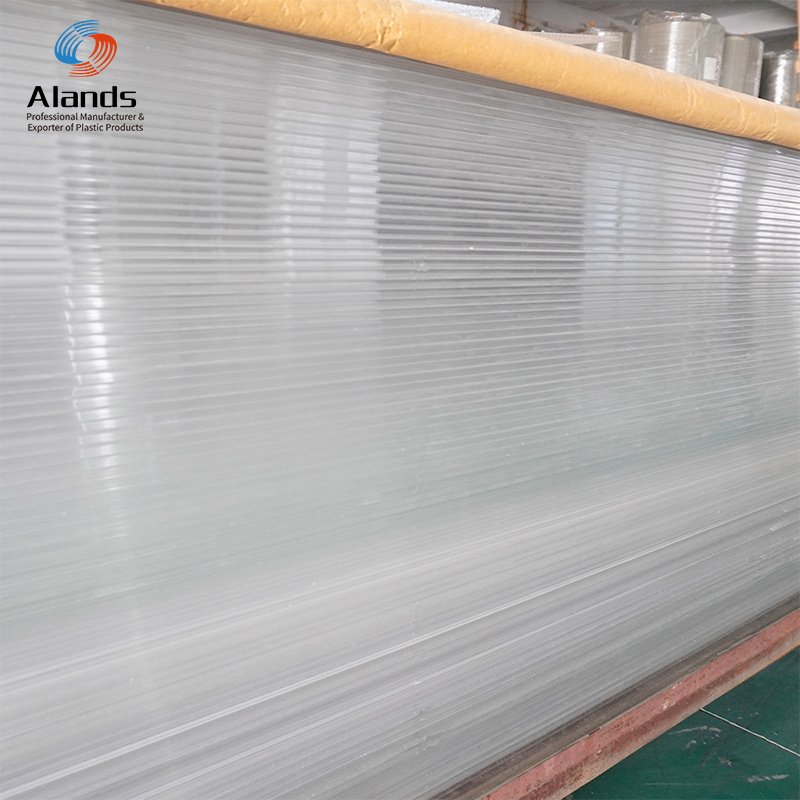

PC hollow sheet

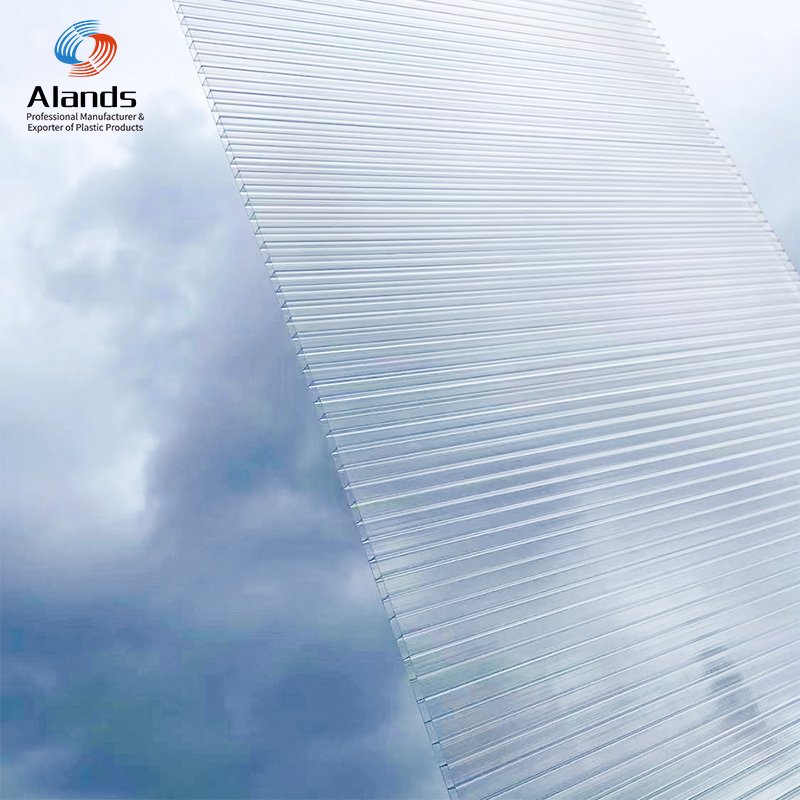

It balances light transmission and thermal insulation, suitable for skylights, carports, greenhouses, corridors, canopies, and other applications.

Compared with glass, it is lighter, tougher, and more weather-resistant.

First-Screen Highlights

High light transmission, not easy to yellow

Impact resistant, safer

Thermal insulation, more energy-saving

UV coating, more weather-resistant

Lightweight & easy installation, saves labor

Sound insulation & noise reduction, quieter

Flame retardant & self-extinguishing, safer

Anti-condensation, clear view

Core Specifications

Material: 100% virgin polycarbonate (PC)

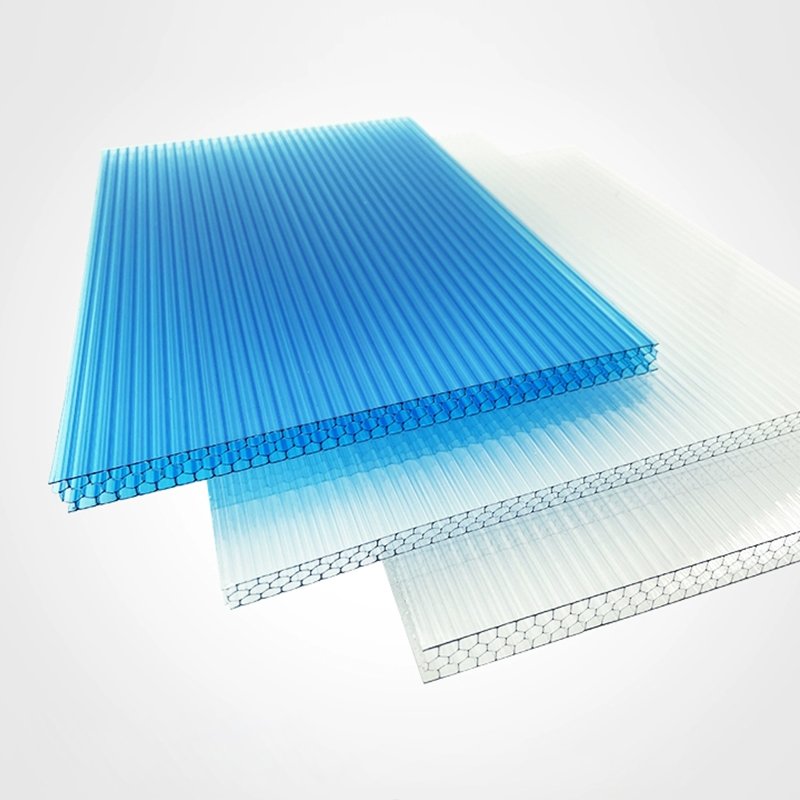

Structure: Double-layer / Triple-layer / Honeycomb cavity (customizable)

Thickness: 4 / 6 / 8 / 10 / 12 / 16 / 20 mm (other thicknesses customizable)

Width: Standard 2.1 m (customizable up to ≤2.6 m)

Length: 6 m / 12 m (custom cut to length available)

Surface: Single-sided / Double-sided UV co-extruded protective layer

Light Transmission Rate: approx. 40%–80% (varies by thickness and color)

Density: approx. 1.2 g/cm³

Thermal Conductivity (K-value): approx. 2.3–3.9 W/(m²·K) (varies by structure)

Flame Retardant Grade: B1 (self-extinguishing when away from fire)

Service Temperature: -40 °C to +120 °C

Warranty: 10 years outdoor (warranty terms vary by region/application)

Colors & Appearance

Transparent | Lake Blue | Grey Blue | Milky White (optional matte / anti-drip / anti-glare)

Applications

Architectural Lighting: Canopies, skylights, corridors, bus shelters, awnings

Home & Garden: Carports, greenhouses, sunroom interior partitions

Agricultural Greenhouses: Seedling houses, flower greenhouses, eco-restaurants

Commercial & Public Buildings: Pedestrian street roofs, grandstand shading, stadium enclosures

Why Choose PC Hollow Sheet (Compared with Glass / Solid PC Sheet)

Lighter: About 1/6 the weight of glass of the same area, reducing structural load

Tougher: Impact resistance hundreds of times higher than ordinary glass, safer

More Energy-Saving: Hollow cavity reduces heat transfer; summer heat insulation, winter heat preservation

More Weather-Resistant: UV co-extrusion layer resists ultraviolet rays, slows yellowing and embrittlement

Easier Installation: Can be cold bent, easily cut, drilled, and installed with H-bars

Design Details

UV Layer: Effectively blocks over 98% of UV rays, preventing aging

Anti-Drip Treatment (Optional): Microporous hydrophilic coating guides condensation into a film, preventing water drops

Sealed Ends: Recommend sealed tape at the top + breathable anti-dust tape at the bottom to prevent dust and mold

H-Bar System: Aluminum/PC H-bars with 3–5 mm expansion allowance for thermal expansion and contraction

Installation Tips

Model Selection: Choose thickness & structure based on span, wind/snow load, and bending radius

Drainage Direction: Install with cavities running vertically for condensation drainage

Expansion Gap: Leave 2–3 mm gap per meter; drill holes 2–3 mm larger than screw diameter

Sealing: Use sealed tape at the top, breathable anti-dust tape at the bottom, and weatherproof sealant on edges

Fastener Spacing: Purlin spacing 600–1000 mm (adjust by thickness/load)

Curved Installation: Minimum cold bending radius ≥ sheet thickness × 175 (varies by structure)

Engineering installation guidance with detailed drawings and spacing charts available on request.

Selection Recommendations (By Application)

Canopies / Carports: 8–10 mm double/triple-layer, milky white or grey blue for better shading

Greenhouses / Garden Rooms: 6–8 mm double-layer, transparent or lake blue, with anti-drip treatment

Corridors / Commercial Roofs: 10–16 mm triple-layer/honeycomb with aluminum H-bar system

Partitions / Screens: 4–6 mm double-layer, matte or milky white for privacy

Frequently Asked Questions (FAQ)

Q: Will it turn yellow?

A: With UV co-extrusion layer, yellowing is slow under normal outdoor use; warranty covers abnormal cases per terms.

Q: How is the heat insulation performance?

A: The cavity structure + surface treatment effectively reduces heat transfer; shading colors further improve cooling.

Q: Can it be bent for arches?

A: Yes, cold bending is possible within minimum bending radius requirements, with cavity direction aligned for drainage.

Q: How to clean and maintain?

A: Use neutral detergent and soft cloth; avoid organic solvents and hard object scratching.

Q: Can size and color be customized?

A: Thickness, length, color, structure, and double-sided UV / anti-drip options are all customizable.

留言表单