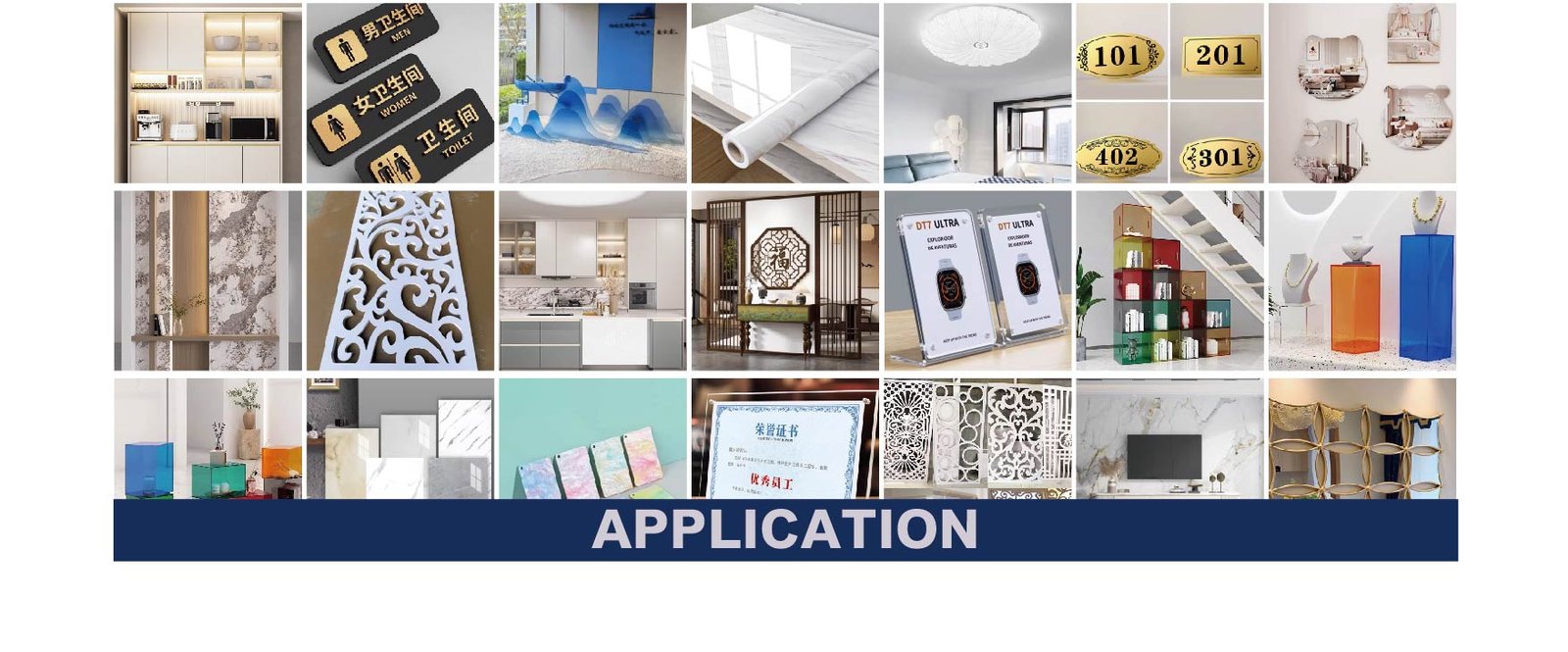

Applications of PVC Foam Board

PVC foam board is a lightweight sheet made primarily from polyvinyl chloride (PVC) through a foaming process. It offers excellent characteristics such as being lightweight, high-strength, moisture-resistant, corrosion-resistant, flame-retardant, and easy to process. It is widely used across various industries due to its versatility and practicality.

1. Construction and Interior Decoration

Wall panels, ceilings, partitions, door panels

Decorative wall backgrounds and protective wall coverings

Interior materials for RVs and containers

Waterproof and corrosion-resistant surfaces in bathrooms and kitchens

PVC foam board is smooth, easy to carve, paint, or laminate, making it an excellent alternative to wood and aluminum composite panels for interior finishing projects.

2. Advertising and Display Industry

Printing substrates, poster backing, signage

Exhibition displays, display stands, POP advertising boards

Cut-out letters, UV printing bases, lightbox backing panels

With its smooth surface and easy fabrication, PVC foam board is a preferred material in the advertising industry, suitable for printing, engraving, and lamination.

3. Furniture Manufacturing

Cabinet back panels, wardrobe dividers, bathroom cabinet doors

Structural panels for indoor furniture, replacement for MDF or particle board

Compared to traditional materials, PVC foam board is more moisture-resistant and less prone to deformation, making it ideal for furniture used in humid environments.

4. Industrial Applications

Equipment enclosures, insulation boards, anti-corrosion panels

Interior linings for electrical cabinets, cleanroom partitions

Its flame resistance and excellent insulation properties make PVC foam board suitable for use in various industrial settings.

5. Crafts and DIY Projects

Handcraft boards, carving sheets, laser-cutting substrates

Educational models, architectural mockups, display props

Lightweight and easy to cut, PVC foam board is a popular choice for hobbyists, model makers, and DIY enthusiasts.